What are the types of corundum blocks?

May 06, 2022

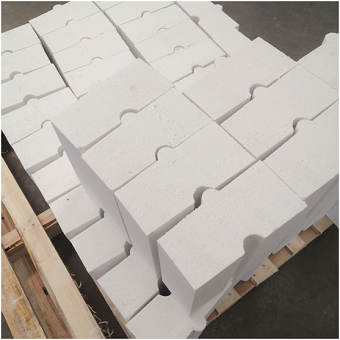

Corundum block is a general term for the refractory block. Corundum blocks are actually more than minute grades and have a variety of different corundum materials.

In general, refractory blocks with aluminum content greater than 85% are called corundum blocks, and corundum can be divided into brown corundum, white corundum, and tabular corundum. Therefore, there are many types of corundum blocks, some are divided according to the aluminum content, some are divided according to different bulk densities; there is the composite refractory block, there is corundum block with different production methods; there are heavy and light corundum block.

Corundum blocks with different substrates are produced according to the use environment of different temperatures, and in most cases, different grades of corundum blocks are made according to the indicators of the manufacturer. Composite corundum blocks include brown corundum and silicon carbide composite block, corundum and silicon nitride composite block, as well as white corundum, tabular corundum, and mullite composite corundum mullite block, corundum mullite block also. There are lightweight, there is a big difference in the bulk density, there is corundum block with different volumes between 1.5, 2.8-3.4; there are also corundum refractory blocks compounded with chrome, chrome corundum refractory block are generally used in waste incinerators lining.

Corundum blocks vary in aluminum content, with an aluminum content between 85-98%. Corundum blocks with a content of more than 95% are cast and formed. They are often used in glass kiln linings and are quite expensive. They are mainly used in The bottom of the glass kiln is resistant to acid corrosion. There are AZS corundum block, corundum mullite block and so on.

If the corundum mullite block is lightweight, it is produced and cut into the required shape, and the bulk density is generally around 1.5. It can be used in the high-temperature insulation layer or directly in the working layer, usually in the lining of light kilns. Such as shuttle kiln lining and some light tunnel kilns.

The heavy corundum block is very widely used, but it depends on the temperature and erosion of different kiln linings. The parts with extremely high temperatures and harsh environments will use white corundum blocks with a bulk density above 3.0, or corundum mullite composite blocks. The composite block combined with corundum and silicon nitride is generally used for furnace doors. This kind of block must have a nitriding pool, and the production method is different from the method of corundum composite brown corundum block.

Corundum block, corundum composite silicon carbide block, and corundum mullite block are all sintered at high temperatures.

So corundum block is just a general term, there are many corundum blocks of different quality; the price is also determined according to different aluminum content, different bulk density, and different production methods.

Relevant information

-

Main properties of magnesium oxide refractory

Performance characteristics of magnesia refractories and other basic refractories Performance characteristics of magnesia refractories and other basic refractories Refractories containing more than 80% ... -

What properties of lightweight insulation fire clay bricks can be improved by the addition of kyanite?

Lightweight insulation fire clay bricks are a kind of shaped refractory material with clay as the main raw material, which is processed, shaped, dried, and calcined with clay. on the kiln. Due to the r ... -

How is the effect of white fused alumina abrasive used in refractory materials?

After mixing, forming, drying, and firing at high temperature in a shuttle kiln. The product has the characteristics of high refractoriness, good thermal shock stability of white corundum, high high te ... -

Characteristics of refractory magnesia chrome bricks for lime kiln

Lime kilns are mainly classified into square kilns and circular kilns. According to the classification of fired products, they can be divided into lime kilns, ceramic kilns, cement kilns, glass kilns, ...