Bricks types of lime kiln

Apr 19, 2022

In recent years, industries such as iron and steel industry, calcium carbide industry, alumina industry and refractory industry are all the popular consumers of lime calcining kilns. Our factory has long-term cooperation with many local lime kiln manufacturers in Jiangxi region, and has rich knowledge in lime kiln. experience.

The classification of lime kiln is mainly divided into square kiln, circular kiln, etc. according to the shape of the kiln; according to the type of products, it is divided into lime kiln, ceramic kiln, cement kiln, glass kiln, brick kiln, etc.; according to the characteristics of flame flow, it is divided into Horizontal flame kiln, rising flame kiln, inverted flame kiln, horseshoe flame kiln, etc.; according to the type of fuel used, it can be divided into coal-fired kiln, oil kiln, gas kiln, etc.; Plate kiln, etc. More generally, it is classified according to the physical state of the baked products and combined with the production method. The kiln type of lime kiln is widely used in the building materials industry, and many of its predecessors are cement kilns used in the cement industry to burn clinker. The choice of refractory bricks for lime kilns is different. Phosphate bricks are used, high-load soft bricks are also used, magnesia bricks are also used, and magnesia-alumina spinel bricks are used.

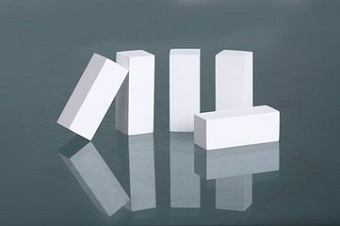

Our long-term supply of high alumina bricks G-2 (345*150*75mm), G-4 (345*150/130*75), G-6 (345*150/120*75) and other refractory bricks, and Unanimously praised by customers, reliable quality, significant energy saving, environmental protection standards, high degree of automation, high quality of finished products, low construction cost, long service life and other advantages are deeply favored by large and medium-sized state-owned and private individual enterprises.

Relevant information

-

Main properties of magnesium oxide refractory

Performance characteristics of magnesia refractories and other basic refractories Performance characteristics of magnesia refractories and other basic refractories Refractories containing more than 80% ... -

What properties of lightweight insulation fire clay bricks can be improved by the addition of kyanite?

Lightweight insulation fire clay bricks are a kind of shaped refractory material with clay as the main raw material, which is processed, shaped, dried, and calcined with clay. on the kiln. Due to the r ... -

How is the effect of white fused alumina abrasive used in refractory materials?

After mixing, forming, drying, and firing at high temperature in a shuttle kiln. The product has the characteristics of high refractoriness, good thermal shock stability of white corundum, high high te ... -

Characteristics of refractory magnesia chrome bricks for lime kiln

Lime kilns are mainly classified into square kilns and circular kilns. According to the classification of fired products, they can be divided into lime kilns, ceramic kilns, cement kilns, glass kilns, ...