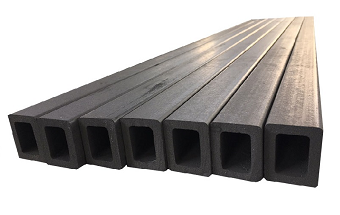

Physical and chemical properties of three silicon carbide bricks commonly used in blast furnaces

Apr 06, 2022

The main feature of silicon carbide bricks is that SiC is covalently bonded and does not have the usual sinterability, and relies on chemical reactions to generate new phases to achieve sintering. In 1985, Si3N4-SiC bricks were used for the first time in the No. 5 blast furnace of Anshan Iron and Steel Co., Ltd. and gained successful experience, and they were quickly popularized and applied in large blast furnaces. At present, the main varieties of high-quality silicon carbide bricks for blast furnaces in my country are Si3N4-SiC bricks, Sialon-SiC bricks, and self-bonding (β-SiC bonding) SiC bricks.

1. Si3N4-SiC brick

Si3N4-SiC brick is a refractory product fired after nitriding with SiC and Si powder as raw materials. SiC and Si3N4 are both covalent bond compounds, and sintering is very difficult. In the multi-graded SiC particles and fine powder, finely ground industrial silicon powder is added, and Si and N2 undergo 2N2+3Si→Si3N4 reaction sintering at high temperature. The Si3N4 generated during the reaction is closely combined with the SiC particles to form a silicon carbide brick with Si3N4 as the binding phase. The study found that most of the Si3N+ bonding phases are needle-like or fibrous structures, which exist around the SiC particles or at the pores of the SiC particles.

2. Sialon-SiC brick

At 1700 °C, in the square phase diagram composed of Si3N4-Al4N4-Al4O6-Si3O6, there is a β-Sialon phase with Si3N4 as the starting point extending to 4/3 (Al2O3, A1N), and the composition changes in a considerable range, There is an O-Sialon phase with Si2N2 as the starting point and extending generally in the direction of the X phase, and the composition changes in a small range. In the production process of Si3N4-SiC products, an appropriate amount of additives is added to make oxygen enter the Si3N4 lattice to generate a certain amount of β-Sialon solid solution phase so that Sialon-SiC bricks can be produced.

3. Self-bonding SiC brick

Industrial silicon and carbon are added to the industrial α-SiC raw materials, and the reaction of Si(s)+C→SiC(s) occurs in a high-temperature reducing atmosphere to generate β-SiC, which is combined with the original high-temperature α-SiC particles, and is produced from Combined with SiC material, the product has good performance. Table 3 shows the physical and chemical indicators of SiC refractory products produced in my country and foreign SiC refractory products. Compared with similar foreign products, all indicators of SiC refractory products produced in my country have reached the level of similar foreign products.

Relevant information

-

Main properties of magnesium oxide refractory

Performance characteristics of magnesia refractories and other basic refractories Performance characteristics of magnesia refractories and other basic refractories Refractories containing more than 80% ... -

What properties of lightweight insulation fire clay bricks can be improved by the addition of kyanite?

Lightweight insulation fire clay bricks are a kind of shaped refractory material with clay as the main raw material, which is processed, shaped, dried, and calcined with clay. on the kiln. Due to the r ... -

How is the effect of white fused alumina abrasive used in refractory materials?

After mixing, forming, drying, and firing at high temperature in a shuttle kiln. The product has the characteristics of high refractoriness, good thermal shock stability of white corundum, high high te ... -

Characteristics of refractory magnesia chrome bricks for lime kiln

Lime kilns are mainly classified into square kilns and circular kilns. According to the classification of fired products, they can be divided into lime kilns, ceramic kilns, cement kilns, glass kilns, ...