Refractory Kaolin Clay Powder

Model Number: hongtai

Certification:

Minimum Order Quantity:

Application of kaolin in refractory industry

Kaolin has a high degree of refractoriness and is commonly used to produce refractory materials. Its products have the ability to withstand high temperatures and withstand loads at high temperatures without deformation. Kaolin, which is mainly composed of kaolinite, and bentonite and bauxite, are collectively referred to as refractory clay according to their high temperature resistance. China's clay with a refractoriness of more than 1580 ° C, bauxite with a refractoriness of more than 1770 ° C, is commonly known as refractory clay. The former is divided into hard clay, soft clay, semi-soft clay, and the latter is called high alumina clay. Some colored kaolins cannot be used in ceramics and papermaking, but are good raw materials for refractory materials. Therefore, refractory materials are an important market for the comprehensive application of kaolin.

There are two main types of kaolin used as refractory products: refractory bricks, silicon aluminum wool. The former has a refractoriness of not less than 1730 ° C, a softening start temperature of 2 × 105 Pa load is not lower than 1350 ° C, and the refrigerating line shrinkage is less than 0.5% (1400 ° C, 2 h), and can be made into various sizes and shapes as needed. brick. The latter is a lightweight refractory insulation material, which is manufactured by kaolin, calcined at 1000 to 1100 ° C, and then melted with an electric arc furnace at 2000 ° C to be blown into cotton under high-speed air flow.

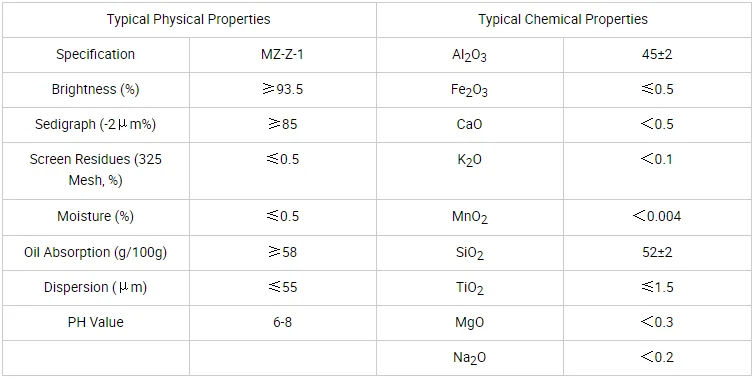

The quality requirements of refractory materials for kaolin are not very strict, but the ratio of the ratio of Al2O3 and SiO2 in kaolin directly affects the change of refractoriness. The value of Al2O3/SiO2 in high quality kaolin is generally between 0.7 and 0.8 or slightly higher. The ratio of Al2O3/SiO2 in pure kaolin is 0.85. When the ratio is greater than 0.85, there is an aluminum-rich mineral, which will improve the refractoriness. When it is less than 0.7, the kaolin content is low, and there is quartz, which will reduce the refractoriness. In addition, the high content of Fe2O3, TiO2 and K2O in kaolin will reduce the refractoriness and have certain harmfulness.

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..