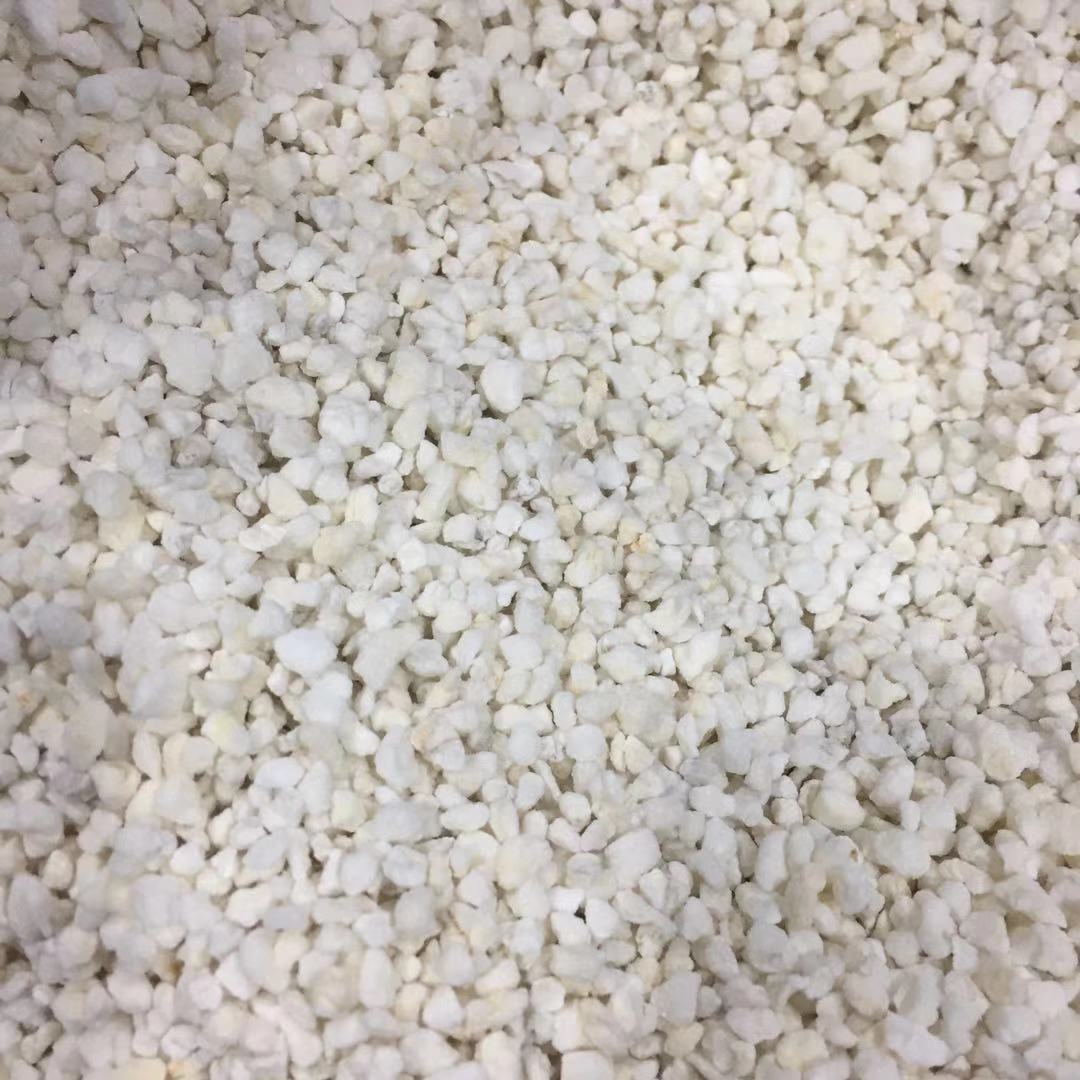

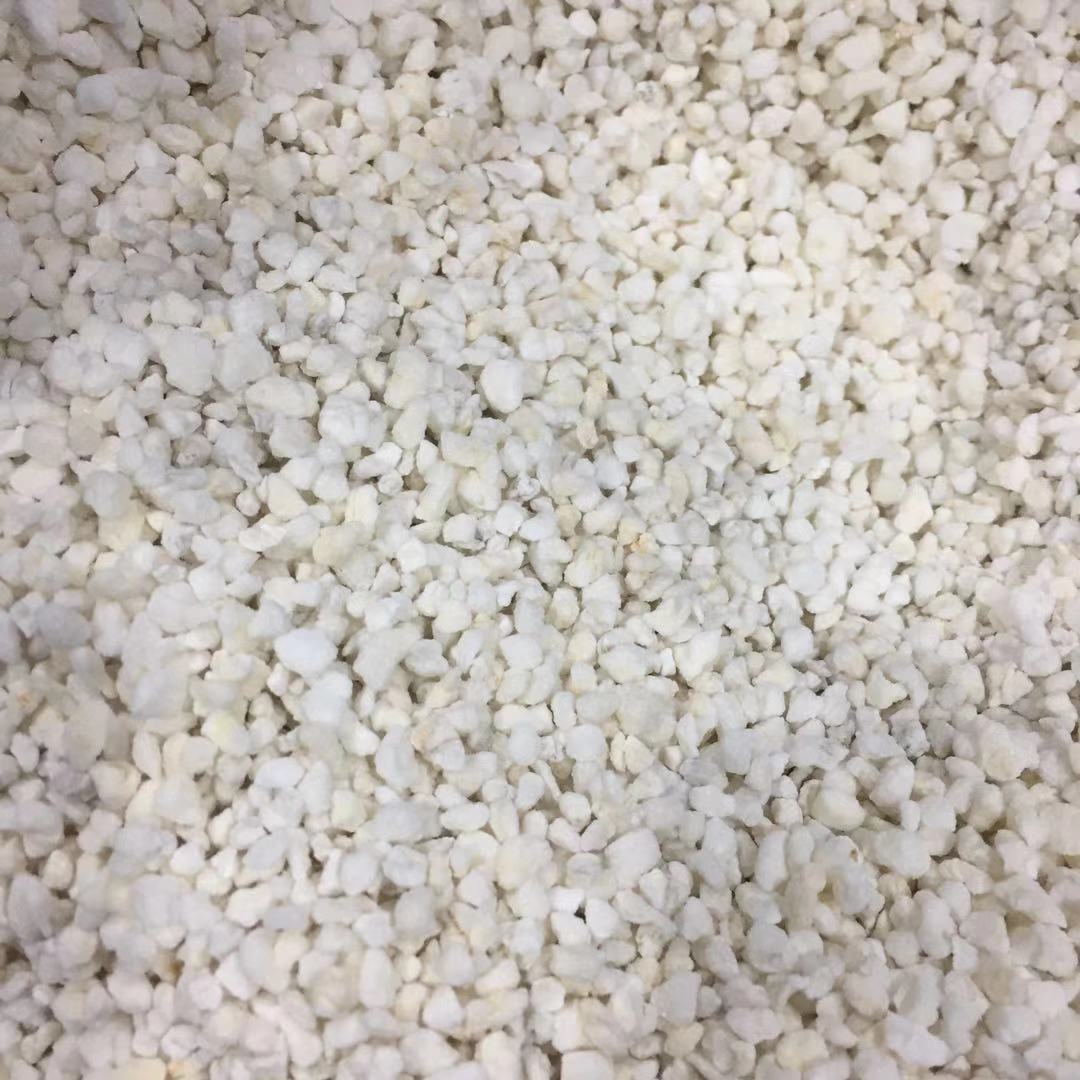

Density 60-100kg/m3 Expanded perlite

Model Number:

Certification:

Minimum Order Quantity:

Perlite Perlite Perlite is a volcanic eruption of acidic lava. The glassy rock that has been rapidly cooled has been named for its pearl-fracture structure. Perlite mines include perlite, obsidian and rosin. The difference between the three is that perlite has a circular arc crack formed by condensation, called perlite structure, water content of 2 to 6%; rosin rock has a unique rosin luster, water content of 6 to 10%; black shale has glass Gloss and shell-like fracture, water content is generally less than 2%.

Perlite • Instructions for use

Main industrial indicators of mineral deposits

The industrial value of the expanded perlite raw materials is mainly determined by their expansion ratio and product bulk density after high temperature roasting.

1. Expansion factor k0>5~15 times

2. The weight is ≤80kg/m3~200 kg/m3

Quality requirements:

1. The glass is pure, the transparency is good, and the light color is mostly high quality.

2. No or slight devitrification, serious is inferior quality.

3. Contains no or little crystal matter, and contains a lot of inferior quality.

4. Chemical composition: SiO2 70%±, H20 4~6%, Fe2O3<1% for high quality, >1% for medium and low quality.

Perlite • Production process

The oxidation and melting temperatures of perlite are: initial shrinkage temperature of 1025 ° C, softening temperature of 1175 ° C, melting temperature of more than 1500 ° C, softening temperature range of 150 ° C, and melting temperature range of 325 ° C. Perlite begins to shrink at a temperature of 120 ° C lower than that of feldspar, a softening temperature of 75 ° C, and a softening range of 95 ° C. Due to these characteristics, perlite can greatly reduce the firing temperature and improve the quality of sintering in the firing of ceramic products. Through further research, the perlite also has a characteristic that the mullite crystals form earlier in the ceramic body containing perlite, which is beneficial to the unfolding of the sintering process. In this way, the perlite-containing green body has the same process characteristics as the feldspar-quartz-clay (kaolin mineral) ternary body blank formulation, and can also reduce the firing temperature (from the original 1280 ° C to 1180 ° C -1160 ° C), and has good thermal stability.

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..