The advantages of magnesia zirconia chimney blocks

May 10, 2022

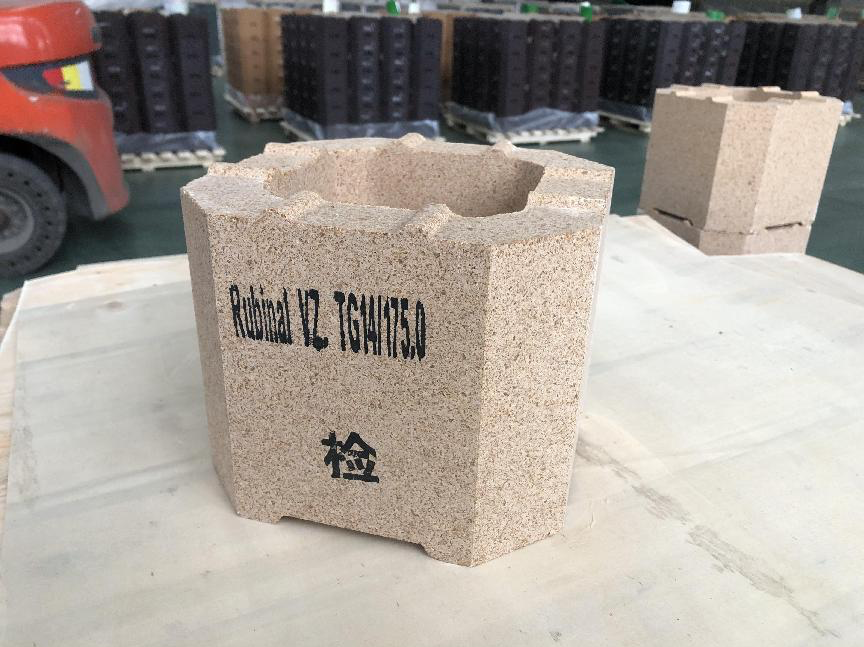

Olivine and baddeleyite have excellent corrosion resistance to alkaline earth metal compounds and sulfides. The magnesia-zirconia block products are mainly used for high-quality lattice laser storage part of the laminated glass kiln heat storage chamber without blockage and collapse.

Sulfide, etc. have good anti-adhesion properties. This commodity is made of fused pipe fittings of magnesia sand and zirconia sand and its subordinate alkaline raw materials. The commodity is dense (apparent density) over 3.08 g/cc). It is also resistant to alkaline corrosive atmosphere and alkaline coal ash corrosion and is commonly used in laminated glass melting furnaces.

Fusion of magnesium and zirconia

1. Immediately add the method

select appropriate raw materials from industrial production to require zirconia, baddeleyite, desiliconized zirconia, zirconia, and other raw materials. Add it now.

2. Electrofusion manufacturing method

Mgo-Zro2 sand is made of electro-melting or calcining, followed by adding the required proportion of raw materials for magnesia blocks.

The advantages of each composed of zirconia

1. Compared with a pure selection of raw materials, the application of zirconia, magnesia-zirconia corundum blocks, and related refractory blocks that are beneficial to calcination are relatively reduced in emission point temperature.

2. At high temperatures, the zirconia oxide is stabilized by drying and solidifying to the zirconia lattice constant.

3. The improvement of Mgo-Zro2, zirconia, the commodity has the following chemical property transformation.

Bulk relative density increase

reduce porosity

Increased temperature and high-temperature compressive strength

What are the characteristics of magnesia zirconia refractory blocks?

1. It is introduced in detail that the amount of zirconia and grain boundary residues is relatively reduced, which in turn increases the softening temperature of grain boundaries and the temperature at which plastic deformation occurs under working pressure.

2. Each has different characteristics from zirconia. When the thermal expansion coefficient, elastic mold, and residual thermal stress subside, bridging the micro-cracks of the two-phase composite type has a lifting effect.

3. In addition to the necessary improvement of zirconia, the actual effect is based on the thermal shock resistance of the raw material, with the increase of zirconia content.

4. Add zirconia to reduce the linear expansion coefficient of the raw material.

Relevant information

-

Main properties of magnesium oxide refractory

Performance characteristics of magnesia refractories and other basic refractories Performance characteristics of magnesia refractories and other basic refractories Refractories containing more than 80% ... -

What properties of lightweight insulation fire clay bricks can be improved by the addition of kyanite?

Lightweight insulation fire clay bricks are a kind of shaped refractory material with clay as the main raw material, which is processed, shaped, dried, and calcined with clay. on the kiln. Due to the r ... -

How is the effect of white fused alumina abrasive used in refractory materials?

After mixing, forming, drying, and firing at high temperature in a shuttle kiln. The product has the characteristics of high refractoriness, good thermal shock stability of white corundum, high high te ... -

Characteristics of refractory magnesia chrome bricks for lime kiln

Lime kilns are mainly classified into square kilns and circular kilns. According to the classification of fired products, they can be divided into lime kilns, ceramic kilns, cement kilns, glass kilns, ...