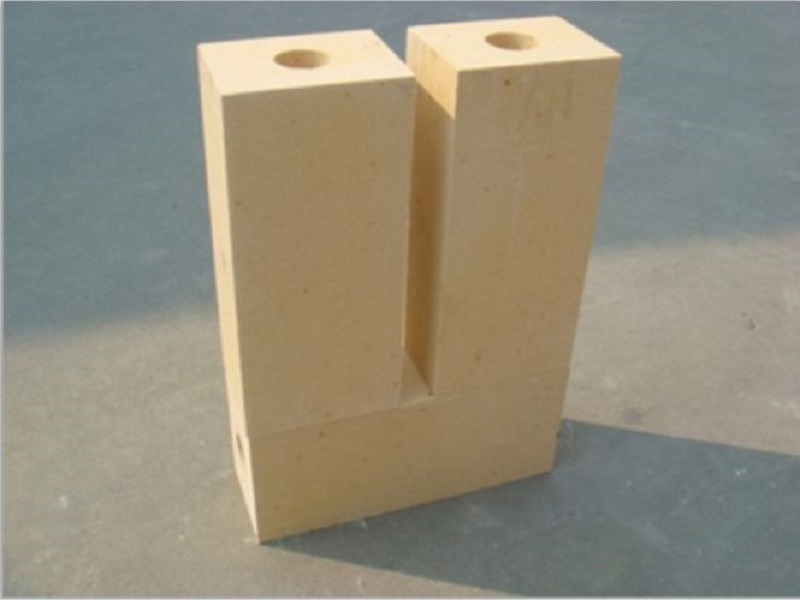

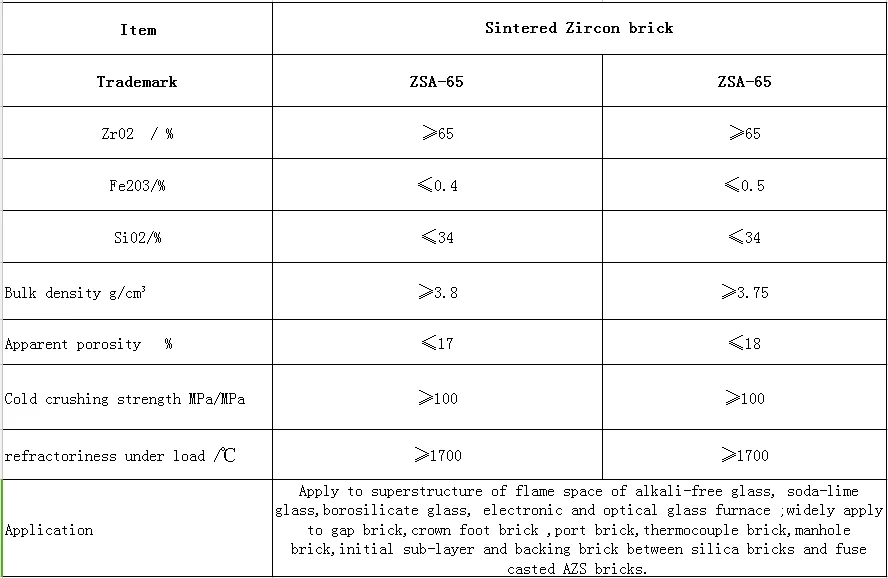

Refractory sintered Zircon Bricks For Glass Furnace

Model Number: hongtai

Certification:

Minimum Order Quantity:

Zircon brick is a refractory brick with zircon as the main phase and is one of the important varieties of zirconium-containing refractories.

(1) Treatment of raw materials.

The raw material of the zircon brick is a selected zircon ore, referred to as zircon sand. It contains about 90% zircon. The zircon concentrate sand has a fine particle size and is single, generally 0.1-0.2 mm. It is not suitable to directly make refractory bricks.

In order to prepare the pure zircon refractory brick with coarse particles, in order to adjust the particle size composition of the refractory brick and reduce the firing shrinkage, the zircon clinker agglomerate is usually prepared by pre-calcining or high-temperature melting of the concentrate sand. When calcining the clinker, firstly grind a part of the concentrate sand into fine powder, mix it with another part of the concentrate sand, and bond it with a temporary organic binder to make the ball or waste, at 1500-1700 ° C (below the decomposition of zircon) Calcined into dense agglomerates at temperature). If an alkali metal oxide or a mineralizer such as MgO or CaO is present, it may be calcined at a lower temperature of 1050 ° C or higher. Zircon sands shrink from 900 ° C at the time of calcination, shrinkage tends to stop at about 1350 ° C, and then expands, and then shrinks sharply after 1700 ° C. The zircon concentrate sand mass is improved in compactness after calcination, and the bulk density can reach 3.5g/cm3 or more. If pure zircon bricks are produced from fine powder, the concentrate sand can be directly calcined at 1450 ° C, quenched by quenching, and then ground.

(2) Production of refractory bricks.

Temporary binders such as sulfite pulp waste, dextrin and lignin should be used in the production of pure zircon bricks. Ethyl silicate, calcium alkylate and phosphoric acid, and water glass can also be used. If a plastic refractory clay is used as a binder, the refractory brick is easy to form and sinter, but it tends to cause a decrease in the refractoriness and volume stability of the refractory brick. Especially when the amount of clay added to the ingredients is high, the effect is particularly significant. In order to promote the sintering of pure zircon bricks, a small amount of CaO or Ca(OH)2, MgO or MgF2 and other mineralizers are often added to the ingredients. This admixture promotes the decomposition of ZrO2·SiO2 at high temperatures and forms a ZrO2 solid solution with ZrO2 and enters the glass phase to promote sintering.

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..