Refractory castable for kilneye

Model Number: hongtai

Certification:

Minimum Order Quantity:

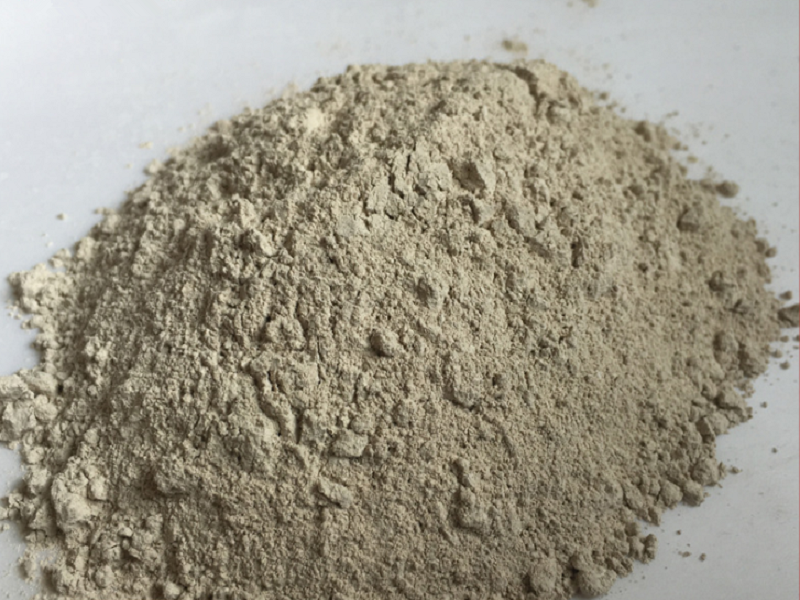

High-aluminum castable refers to refractory castable with Al2O3 content greater than 48%. It has the characteristics of high thermal strength, good wear resistance, thermal shock resistance, anti-flaking and good volume stability at high temperature. Its application is very extensive, such as cement kiln head, kiln tail, cyclone preheater, tertiary air duct, grate cooler, refining furnace cover, blast furnace, heating furnace, etc.

Refractory fire castable,The traditional lightweight high-aluminum castables have a high thermal conductivity due to their large pore diameter and can only be used at low temperature (≤1200 °C). It is known from the conventional principle that if the material can form a closed circular microporous structure inside, the thermal conductivity can be significantly reduced. In order to improve the performance of lightweight high-alumina castables, high-performance lightweight high-aluminum castables with lower thermal conductivity, higher strength and volume stability have been developed by adding pore-forming agents.

Refractory fire castable,The scientific formula further improves the high temperature strength and thermal stability of the castable series refractory material, and effectively controls the calcium oxide content, reduces the eutectic phase of the material, thereby improving the refractoriness, high temperature strength and slag resistance. This series of castables is mainly composed of refractory high-aluminum raw materials, using new micro-powder technology and high-efficiency composite chemical additives. The load softening temperature is high, the service life is long, and the construction is convenient. It has obvious effects on improving heat preservation, reducing heat energy loss and reducing environmental working temperature.

Refractory fire castable, Applicable to heating furnace, soaking furnace, heat treatment furnace, rotary kiln; various high temperature burner lining, heating furnace tube lining, refining equipment parts outside molten steel furnace and high temperature wear resistant lining of petrochemical catalytic cracking reactor; blast furnace The iron sulcus, the iron furnace trough of the iron furnace, and the integral powder gun for pretreatment of molten iron are used. It can also be used to make large precast blocks and linings for quick construction.

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..