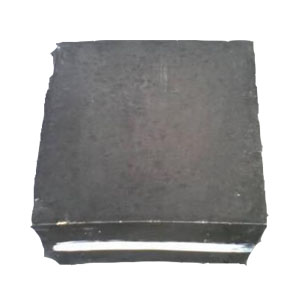

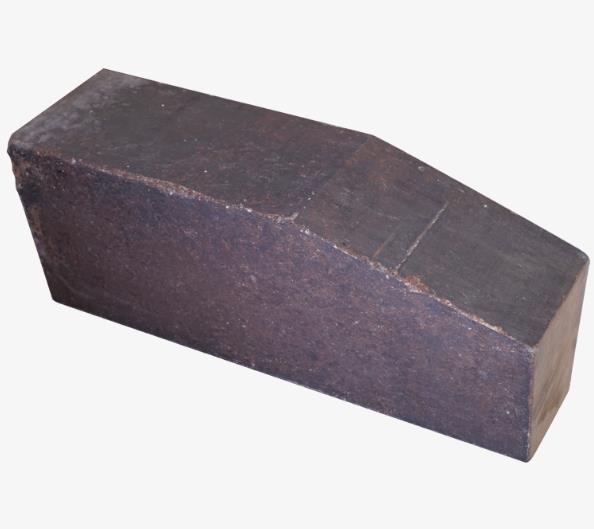

Semi-rebonded magnesia chrome brick for Metallurgical industry

Model Number:

Certification:

Minimum Order Quantity:

Semi-rebonded magnesia chrome brick for Metallurgical industry

Semi-recombined magnesia-chrome bricks refer to refractory products fired from partially fused magnesia-chrome sand. The main mineral composition of semi-recombined magnesia-chrome bricks is periclase, spinel and a small amount of silicate. The grains are of opaque structure, the spinel in the periclase crystal is fully developed, and the matrix part is of a metasomatic turbidity structure. The inter-crystal is the direct combination of periclase-periclase or periclase-spinel, and the silicate phase exists between the crystal grains in an isolated state. The thermal shock resistance of semi-recombined magnesia-chrome brick is better than that of direct combination. Magnesia chrome brick.

Manufacturing process

The fused magnesia-chromium material is used as granules, and some chrome ore and magnesia are added or sintered to synthesize magnesia-chromium material as fine powder, and bricks are made according to the conventional process. The fused magnesia name material should be smelted in a weak oxidizing atmosphere, and there should not be a lot of reducing phase in the material, and metal iron and chromium should not be avoided; magnesia and chromite used as fine powder must be ground together, and the fineness should be guaranteed. Less than 0.088mm accounts for more than 95%; using a high-tonnage brick press to form, the brick density is greater than 3.2g/cm3. After the bricks are dried, the moisture content of the kiln is less than 1.0%. The products are fired in a tunnel kiln, the firing temperature is above 1750°C, and a weak oxidizing atmosphere is maintained in the kiln

Characteristic

Semi-recombined magnesia-chrome bricks are dense, low porosity, high temperature strength, better thermal shock resistance than recombined magnesia-chrome bricks, and have strong slag erosion resistance. It can be used in vulnerable parts of steelmaking electric furnaces, RH, DH vacuum degassing devices, secondary refining slag lines such as VOD, LF, ASEA-SKF, AOD and other severely eroded parts, copper smelting converter tuyere area, cement rotary kiln firing zone and glass furnace regenerator.

Application

Semi-recombined magnesia-chrome bricks have lower cost and better thermal shock resistance than recombined magnesia-chrome bricks with similar compositions, and can replace recombined magnesia-chrome bricks within a certain range.

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..