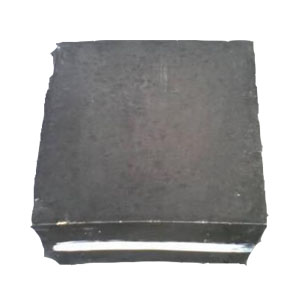

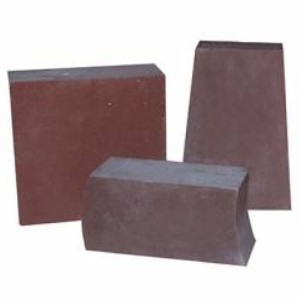

Fuse-Rebonded Magnesia-Chrome Brick

Model Number: Hongtai

Certification: ISO9001

Minimum Order Quantity: 1 ton

Fuse-Rebonded Magnesia-Chrome Brick

The Fuse-Rebonded Magnesia-Chrome Brick is also called fused grain magnesia chrome brick. High temperature performance is between fused cast magnesia chrome brick and sintered magnesia chrome brick, and its load softening temperature can reach 1700 degrees Celsius

Application of Fuse-Rebonded Magnesia-Chrome Brick in copper converter

The use of high-performance magnesia-chrome bricks in the tuyere of the copper converter has been widely promoted. The tuyere area is the most vulnerable part of the copper converter. The main reasons are:

(1) The operating temperature of this part is relatively high, and the temperature fluctuation is large. The temperature change rate before and after the addition of the copper crucible reaches 40 ° C / min or more;

(2) erosion, infiltration of high temperature melts and erosion of gases and melts;

(3) The adoption of new smelting technologies, such as the use of oxygen-enriched blowing technology in the 1990s, made the use of refractory materials in this area more demanding. Therefore, only by continuously improving the magnesium chrome bricks in this part can we adapt to the development of converter smelting technology and improve the service life of the converter.

| Fuse-Rebonded Magnesia-Chrome Brick | ||||||||

| Brand |

RT-FRM Ge-12 |

RT-FRM Ge-14 |

RT-FRM Ge-16 |

RT-FRM Ge-18 |

RT-FRM Ge-20 |

RT-FRM Ge-22 |

RT-FRM Ge-26 |

|

| MgO% | ≥ | 68 | 65 | 60 | 58 | 55 | 50 | 45 |

| Cr2O3% | ≥ | 12 | 14 | 16 | 18 | 20 | 22 | 26 |

| SiO2% | ≤ | 1.2 | 1.4 | 1.4 | 1.5 | 1.5 | 1.5 | 1.5 |

| Bulk Density (g/cm3) | ≥ | 3.00 | 3.05 | 3.08 | 3.10 | 3.15 | 3.20 | 3.25 |

| Apparent Porosity % | ≤ | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

Application of Fuse-Rebonded Magnesia-Chrome Brick

At present, refractory materials for RH furnaces are mainly Fuse-Rebonded Magnesia-Chrome Brick. Compared with other refining equipments, RH vacuum chambers are refractory materials in addition to high temperature steel water and slag during the treatment process. They also suffer from high-speed erosion of steel and rapid temperature changes. Therefore, more stringent requirements are imposed on refractory materials. However, with the increase of smelting strength and the continuous change of smelting steel grades, the service life of existing magnesia chrome bricks can no longer meet the requirements of energy saving and consumption reduction. In order to solve this problem, the development of the original magnesia chrome bricks has been carried out to produce high-performance Fuse-Rebonded Magnesia-Chrome Brick, and good results have been obtained in Baosteel's furnace application.

In order to improve the performance of the existing Magnesia-Chrome Brick, fused fused chrome sand and chrome ore with high Cr2O3 content and high purity are the main raw materials. The effects of Cr2O3 content and additives such as high-purity magnesia, TiO2 and Cr2O3 micropowder on the properties of magnesia-chrome bricks were studied.

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..