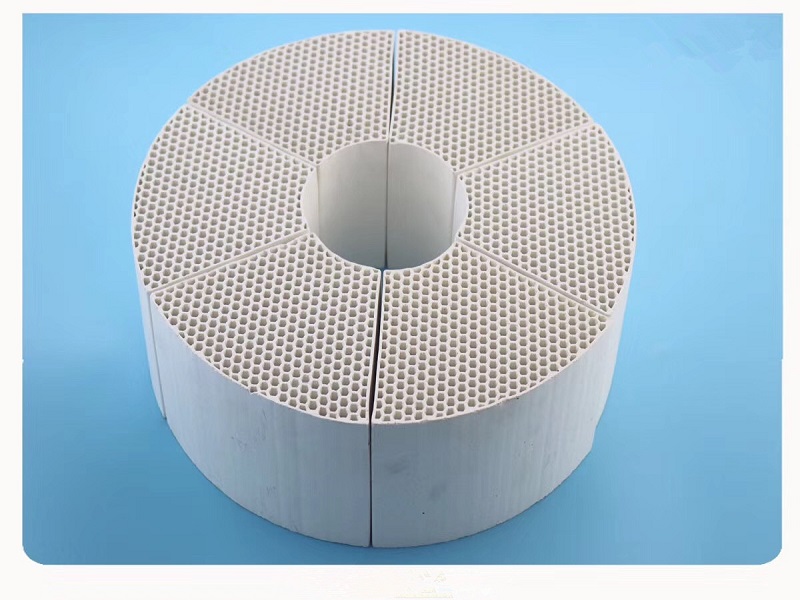

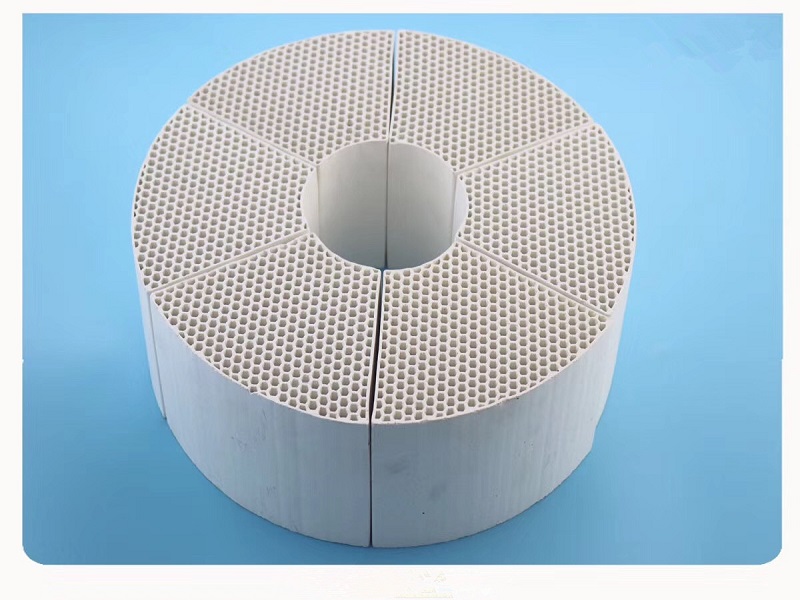

Honeycomb Ceramic Regenerator

Model Number: hongtai

Certification:

Minimum Order Quantity:

Regenerative high temperature air combustion (HTAC) is a new combustion technology with great energy saving and environmental protection. The regenerator is a key component of regenerative burners. It is widely used in steel, machinery, building materials, petrochemical, and colored. In various furnaces, hot blast furnaces, heat treatment furnaces, cracking furnaces, roasters, melting furnaces, soaking furnaces, oil and gas boilers, etc. in the metal smelting industry, the technology is to make two regenerators through the reversing device. Alternate endothermic heat release, maximally recover the heat of the flue gas, and then heat the combustion air and gas to above 1000 °C, even low-calorie inferior fuel (such as blast furnace gas) can achieve stable ignition and efficient combustion, saving fuel 40 to 70%. The output is increased by more than 15%, the oxidized burning loss of the billet is reduced by more than 40%, the NOx emission is less than 100ppm, and the flue gas discharge temperature is lower than 160 °C, which greatly reduces the global greenhouse effect. If most industrial furnaces and kiln in the country adopt HTAC technology, its economic and social benefits are immeasurable, which will greatly alleviate the shortage of energy and effectively improve the living environment of human beings.

The regenerators are mainly composed of honeycomb ceramics, heat storage balls and heat storage tubes. The specific surface area of the honeycomb ceramic is more than 5 times that of the small ball, the heat transfer capacity is 4 to 5 times larger, and the airflow resistance is only 1/3 of the small ball, and the heat penetration depth is small. Therefore, honeycomb ceramics are more conducive to low-oxygen combustion than heat storage balls, so that the furnace temperature is uniform, the heat transfer rate is fast, and the steel can be quickly tapped, which greatly reduces the oxidation burn and the formation of NOx gas, and significantly improves the environmental protection and energy saving effect. The volume of the regenerator with honeycomb ceramics is greatly reduced, and a sufficient amount of burners can be arranged to meet the heat load requirements. The direct airflow passage of the honeycomb ceramic is more difficult to block than the labyrinth passage of the small ball, and the self-cleaning property is good, and is more suitable for the uncleanness of burning in China.

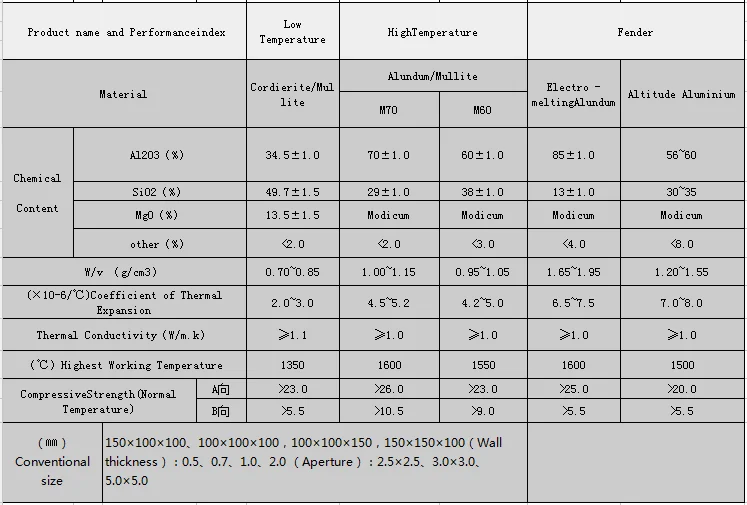

Corundum/mullite, cordierite/mullite composite phase honeycomb ceramic regenerator has remarkable advantages such as high temperature resistance, acid and alkali corrosion resistance, good thermal shock resistance, high strength, large heat storage capacity and good thermal conductivity. And the service life is greatly improved.

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..